.png)

Remember that value is determined by the customer. Understanding your current process quality capabilities versus customer expectations

SIX SIGMA MEANS VERIFICATION

Sigma level is often used as a way to understand the current quality capabilities of a process, how this level matches up with customer expectations, where possible areas of improvement may reside, and as verification that a process improvement project has had the intended effects. This article goes into additional details regarding the formula as well as more information on how the formula is designed. This page will also give you defect percentage and yield values to expect over time.Ĭertain advanced understandings for sigma level can be found here. The calculation will factor in the 1.5 sigma shift over time and give you the sigma level for the process.

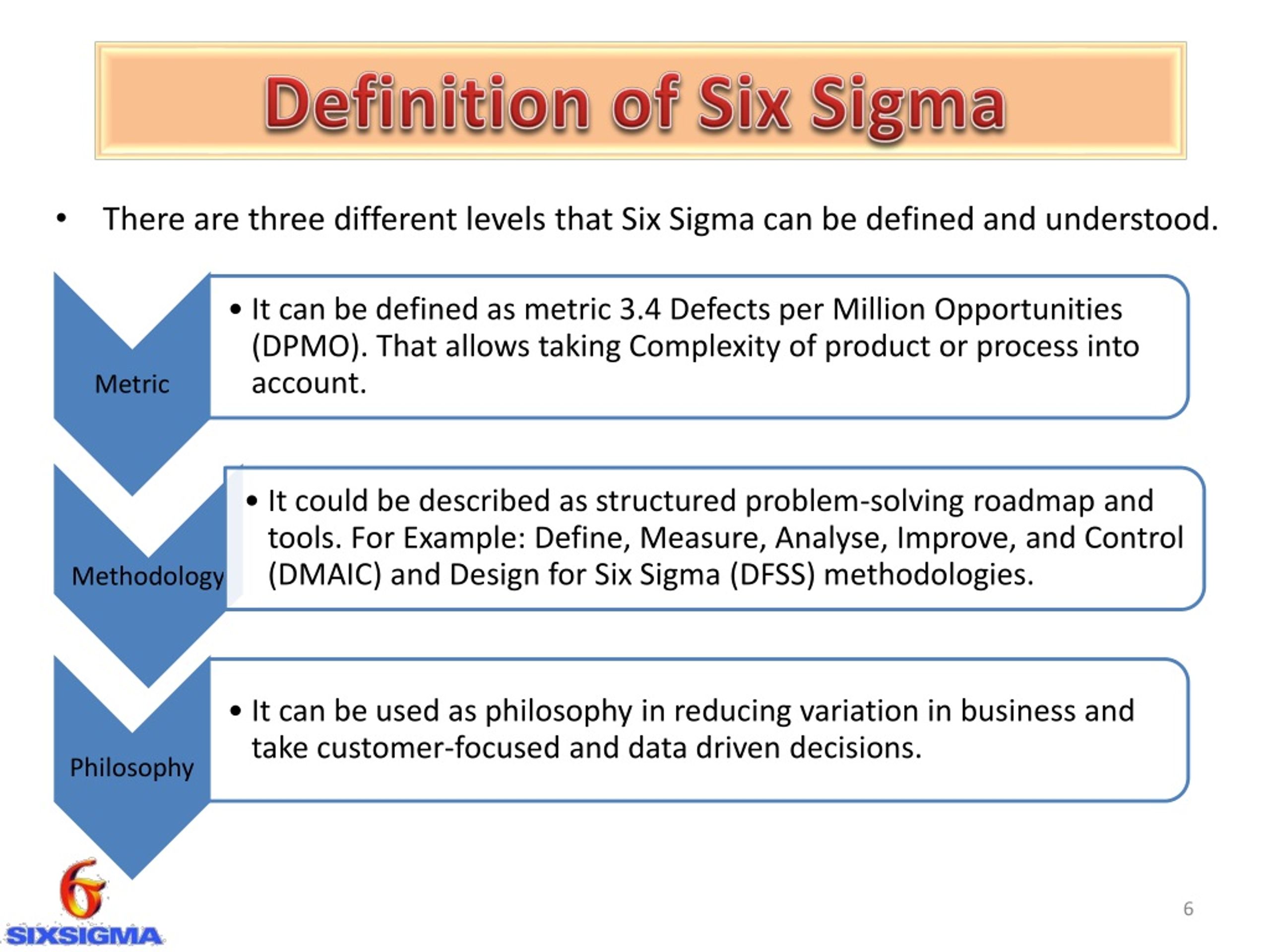

Next, find a sigma level conversion table to determine the sigma level. Start by calculating the defects per million opportunities (DPMO) as it is currently understood. The actual calculation for sigma level is commonly calculated by using a spreadsheet or online conversion webpage. The goal of many programs - a goal few would meet - was to reach a specification limit of +/- 6-sigma, or 3.4 defects per million. Assuming normal distribution and normal variation of the mean, the specification limits would need to be set at a particular sigma level to achieve the desired defects per million opportunities level.įor example, if the long-term desired maximum defects per million was 6,210 defects per million opportunities, factoring in the 1.5 sigma shift over time, a specification limit of +/- 4-sigma would be required. Motorola engineers discovered that many of their operations were prone to shift 1.5 sigma over time. It is this sigma level that leads to the term Six Sigma, which is a philosophy of delivering near perfect products or services by eliminating variabilities that lead to defects. A level of 6-sigma represents a high level of quality, with 3.4 defects per million opportunities. Sigma level is a statistical calculation that takes short-term information regarding the defects per million opportunities (DPMO) of a process, factors in the inclination of a process to shift over time, and gives a level value score representing the modified DPMO with shift in an attempt to help determine if the quality capability of the process can meet customer requirements over time.įor example, 1-sigma represents a poor level of quality, with 691,462 defects per million opportunities over time, which demonstrates a failure rate of over 69.1%. What does sigma level mean? An overview: What is a Sigma level? The last response elicits a half smile from you, but you walk away not really understanding this metric. I’ve been told higher is better for quality, but I don’t know why. You ask a supervisor while touring the production floor, but all you get in response is, “I really don’t have any idea what these numbers mean. What do these numbers represent? Which line is doing better? Production line 1 has a sigma level of 3.4, while production line two has a sigma level of 4.8. It is the first week on the job, and you find yourself looking over the various processes of the new company.

0 kommentar(er)

0 kommentar(er)